Curing

Fresh turmeric is cured for obtaining dry turmeric. The fingers are separated from mother rhizomes. Mother rhizomes are usually kept as seed material. Curing involves boiling of fresh rhizomes in water and drying in the sun. In the traditional method of curing, the cleaned rhizomes are boiled in water just enough to immerse them. Boiling is stopped when froth comes out and white fumes appear giving out a typical odour. The boiling should last for 45-60 minutes when the rhizomes become soft. The stage at which boiling is stopped largely influences the colour and aroma of the final product. Over cooking spoils the colour of the final product while under-cooking renders the dried product brittle.

Use turmeric boiler TNAU model 100 kg capacity especially for commercial growers and steam boil for 60 minutes. This method reduces drying time to 10 days and improve quality and cleanliness.

Drying

The cooked fingers are dried in the sun by spreading them in 5-7 cm thick layers on bamboo mats or drying floor. A thinner layer is not desirable, as the colour of the dried product may be adversely affected. During night time, the rhizomes should be heaped or covered with material, which provides aeration. It may take 10-15 days for the rhizomes to become completely dry. Artificial drying, using cross-flow hot air at a maximum temperature of 60°C also gives a satisfactory product. In the case of sliced turmeric, artificial drying has clear advantages in giving a brighter coloured product than sun drying which tends to undergo surface bleaching. The yield of the dry product varies from 10-30% depending upon the variety and the location where the crop is grown.

Polishing

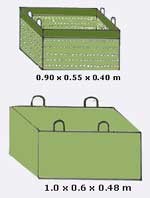

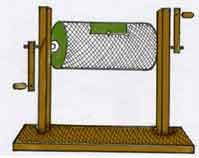

Dried turmeric has a poor appearance and a rough dull outer surface with scales and root bits. The appearance is improved by smoothening and polishing the outer surface by manual or mechanical rubbing. Manual polishing consists of rubbing the dried turmeric fingers on a hard surface. The improved method is by using a hand operated barrel or drum mounted on a central axis, the sides of which are made of expanded metal mesh. When the drum filled with turmeric is rotated, polishing is effected by abrasion of the surface against the mesh as well as by mutual rubbing against each other as they roll inside the drum. Turmeric is also polished in power-operated drums. The yield of polished turmeric from the raw material varies from 15-25%.

Colouring

The colour of the processed turmeric influences the price of the produce. For an attractive product, turmeric powder (mixed with little water) may be sprinkled during the last phase of polishing.